V.A.V. Group is a manufacturer of silicone and TPE/TPV profiles, but also of various assembly products, such as pressure profiles. Pressure profiles and the attached metal valves are used for example for washers in the pulp and paper industry all over the world. Other usage scenarios are, for example, the waterproofing of the compartments of some special vehicles. Pressure profiles are made from V.A.V. Group’s own silicone profile.

Pressure profiles in hatches and openings create a true liquid proof seal. Air-to-air mixing is minimized.

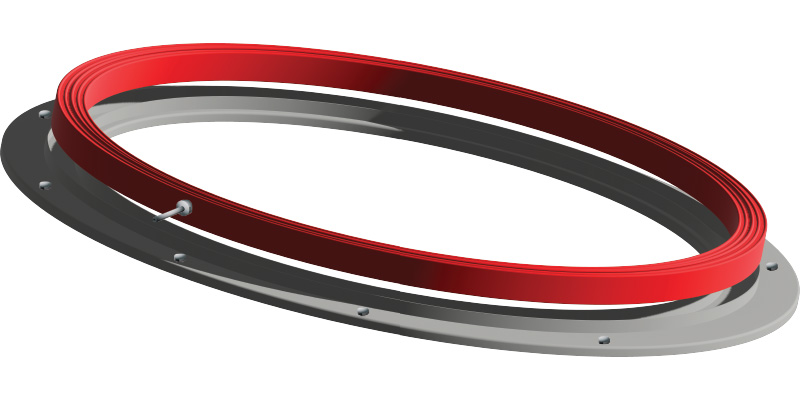

The silicone used for pressure profiles goes through further processing to ensure that it can withstand the pulp washers‘ harsh mechanical and chemical wear and tear. The profiles and valves must endure various conditions, from the fast spinning motion to different acids and alkalines used in the bleaching and washing phases. Pressure profiles are made according to the drum’s measurements, and finished profiles are connected to metallic valves, which direct air to tightly seal the profiles.

We at V.A.V. Group are happy to assist in the product development of the pressure profiles and valves. We place high importance on quality assurance and therefore conduct several inspections throughout the assembly process to ensure safe and high-quality products.

Do you need help finding the best solutions for your needs? Contact us today!

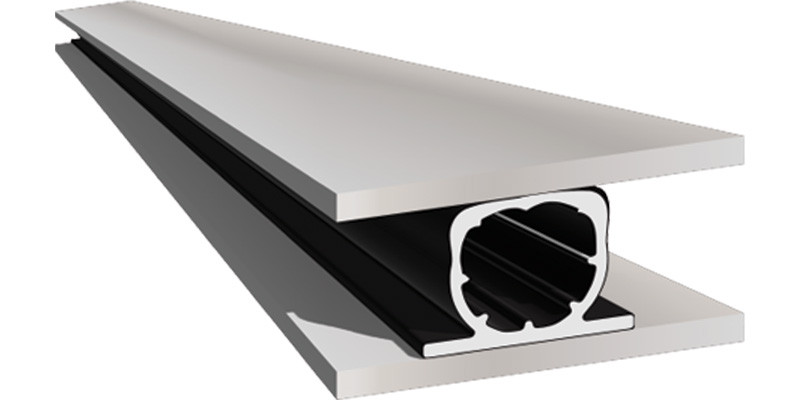

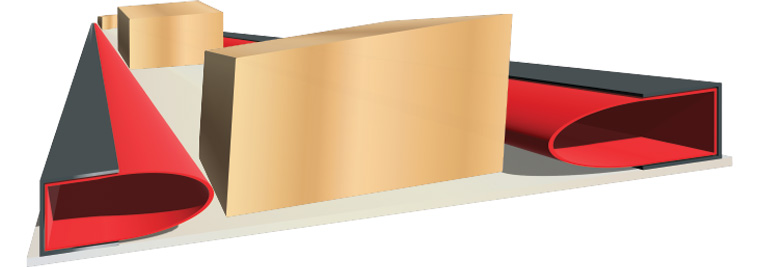

- No compression

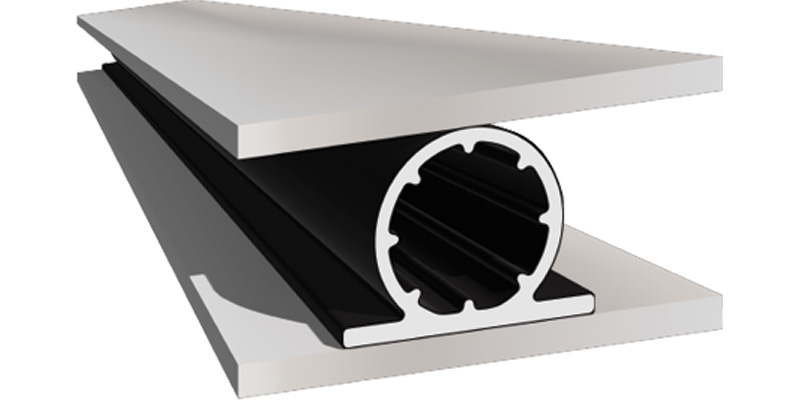

2. Compression, hollow profile

3. Compression, pressure profile

Where pressure profiles can be used?

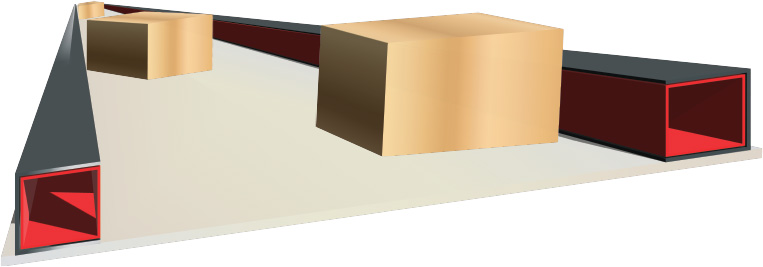

There is a huge range of usage scenarios for pressure profiles. From spaceship hatches to centering items on an conveyor belt, pressure profiles are a cost effective and lasting solution to many problems that usually use with other kind of pneumatics, robotics or even manual work.

Here are few examples of inflatable seal use cases:

- Paper industry (suction rollers, scraper bars, cutters, pulp mashers etc.)

- Telecommunications industry (semiconductor processing, filters, actuators, scrubbers, robotics, optics)

- Shipbuilding (portholes, lift platforms, loading hatches, drive shaft maintenance)

- Textile industry (clamping, door seals of pressure chambers)

- Chemical industry (processing equipment, mixers, hoppers, chutes, valves)

- Metalworking industry (door seals, scraper bars, continuous steel casting, furnace sealing)

- Food industry (autoclaves, chambers, cutters)

- Transport (door seals on high-speed trains, specialized transport containers)

- Pharmacy (mixers, robotics, autoclaves, ovens, clean and sterile rooms)

Centering boxes on an conveyor belt with specialized pressure profiles

What are the main advantages of inflatable sealing profiles?

- Variable sealing gap – Inflatable seals are suited to applications where sealing gaps vary. Inflatable seal can expand to conform around uneven surfaces.

- Airtight seal – Silicone inflatable seals can form airtight seals and are used in many medical and pharmaceutical applications.

- Watertight seal – Silicone inflatable seals can form watertight seals making them an ideal choice for a variety of marine and rolling stock applications.

- FDA approved – Our silicone inflatable seals can be made from FDA certified materials, making them suitable for use in food processing applications. Inflatable sealing also usually uses less tactile surfaces.

- Chemical resistant – We are able to manufacture inflatable seals from chemical resistant materials (seal and connectors) used for example in pulp industry.